Part 6-Mining Opals

Mining Opals

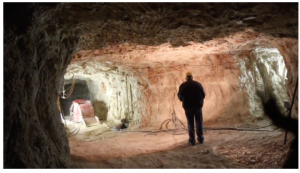

A variety of tools are needed to mine the opals, some more complex or more effective than others. There has been a rapid increase in the use of mining machines since the 1970s. Tunneling machines with revolving cutting heads and small underground front-end loaders (boggers) have been introduced to streamline opal mining and dramatically increase productivity.

Miners soon saw the benefits of technology – drilling test shafts to gauge their chances before beginning serious excavation, using jackhammers instead of pickaxes, blasting with dynamite, or bringing in the bulldozers. Bulldozers are employed to remove overburden and expose the level where it is shallow. Spotters follow behind watching for traces of opal, and any seam found is then worked over by handpick.

A variety of tools are needed to mine the opals, some more complex or more effective than others. There has been a rapid increase in the use of mining machines since the 1970s. Tunneling machines with revolving cutting heads and small underground front-end loaders (boggers) have been introduced to streamline opal mining and dramatically increase productivity.

Boulder opal is one of the rarest and most valuable forms of opal found in Australia and makes up less than 5% of all opal mined. It is very sparsely distributed through South West Queensland. It is predicted that boulder opal is going to run out in the next 10 years because of the difficulty clearing Native Title and EPA requirements of rehabilitation. Native Title is the process of gaining agreement from the local Aboriginal tribes before mining takes place. This is an extremely difficult and time consuming process. The EPA requirement is that all mines need to be “back-filled” and trees planted when the mining is finished. This process alone can send a miner bankrupt if he has not found “colour” in his “dig”. Added to this are the onerous paperwork requirements, with “enough forms to sink a ship” the average miner just does not have the motivation to comply with all of the government regulations. So, as a result there are fewer and fewer miners on the field!

WHICH FIELD DID MY BLACK OPAL COME FROM?

There are over 200 opal mining fields in Lightning Ridge, however, most of Australian Opal Cutters Black Opal comes from the following mines:

Bald Hill

One of the only ‘Walk-In’ mines at Lightning Ridge, most of the precious Opal found in this area was recovered from the main workings over an area of only 120 metres by 30 metres! Visitors can walk through the mine from 9am to 5pm daily with self-guided tours or coach tours.

Deep-Four Mile

In the 1930’s, miners extracted good quality Opal from five claims at Deep-Four Mile, with the deepest shaft spanning over 28.5 metres.

Hawks Nest

Sinking at this site ranged from 1.2 metres to 12 metres, with lenses up to 2.7 metres thick still present, producing good quality precious Opal. In some of the shafts three Opal bearing lenses at 3.6 metres, 6.9 metres and 12 metres were intersected.

Nebea Hill

Discovered in 1973, this mine is thought to be one of the most productive mines in the area. It was estimated that eight claims produced over $3,000,000 worth of Opal over two years. Mining techniques used on site over the years began with large-scale open-cut mining, followed by underground mining.

New Chum and Old Chum

A Opal stone of 100 carats was recovered from the New Chum area of this site and Opal float was found in gravel on the side of the hill in the Old Chum area.

New Rush (New Nobby)

Mined in the 1960’s with a maximum shaft depth of 12 metres, this site returned precious Opal, which resulted in a rush to the area and the sinking of about 100 shafts.

Nine Mile

One of the most worked fields still being worked today, shafts stretch to 12 metres deep on the crest of the hill. Potch was found interspersed with Opal in this area.

Rouses-Six Mile

The exact location of this area is uncertain; however, it is known to be closed to McDonald’s Six Mile. Only two claims produced significant quantities of Opal in this area and much of the Opal was in the form of big Black Nobbies.

Shallow Belars

As the name suggests, this field is quite shallow, with a depth of 0.3 metres to 3.6 metres. Good quality Opal has been recovered at this site and consisted of opalised bivalves.

The Old Nobby

One of the first shafts on the Lightning Ridge field was sunk at Nobbys and Opal was initially found in the gravel at the foot of the ridge. Although the rocks are extremely difficult and hard to work, a considerable amount of Opal has been recovered from a lens depth of 6 metres.

The Three Mile

One of the most famous and overworked mines, this field has peaked at over 1,000 people engaged in Opal mining there at one time. By far one of the most productive areas on the field, large-scale open cut mining has been carried out in recent years.

The Six Mile

Also known as McDonald’s Six Mile, the depth to the Finch clay facies ranges from 9 metres to 12 metres on the crest of the hill and 1.8 metres at the base of the hill, with the best Opal found deeper in the ground.

Thorley’s Six Mile

This field was first mined in 1902 from a range of 6 to 12 metres and then rediscovered by miners in the 1970’s, as the field continue to produce high quality Black Opal.

INTERVIEW WITH “LAHOUD OPALS” EDMOND

INTERVIEW WITH “OUTBACK OPAL HUNTERS” GEORGE