Part-7 Taking Care Of Opals

Taking Care of opals

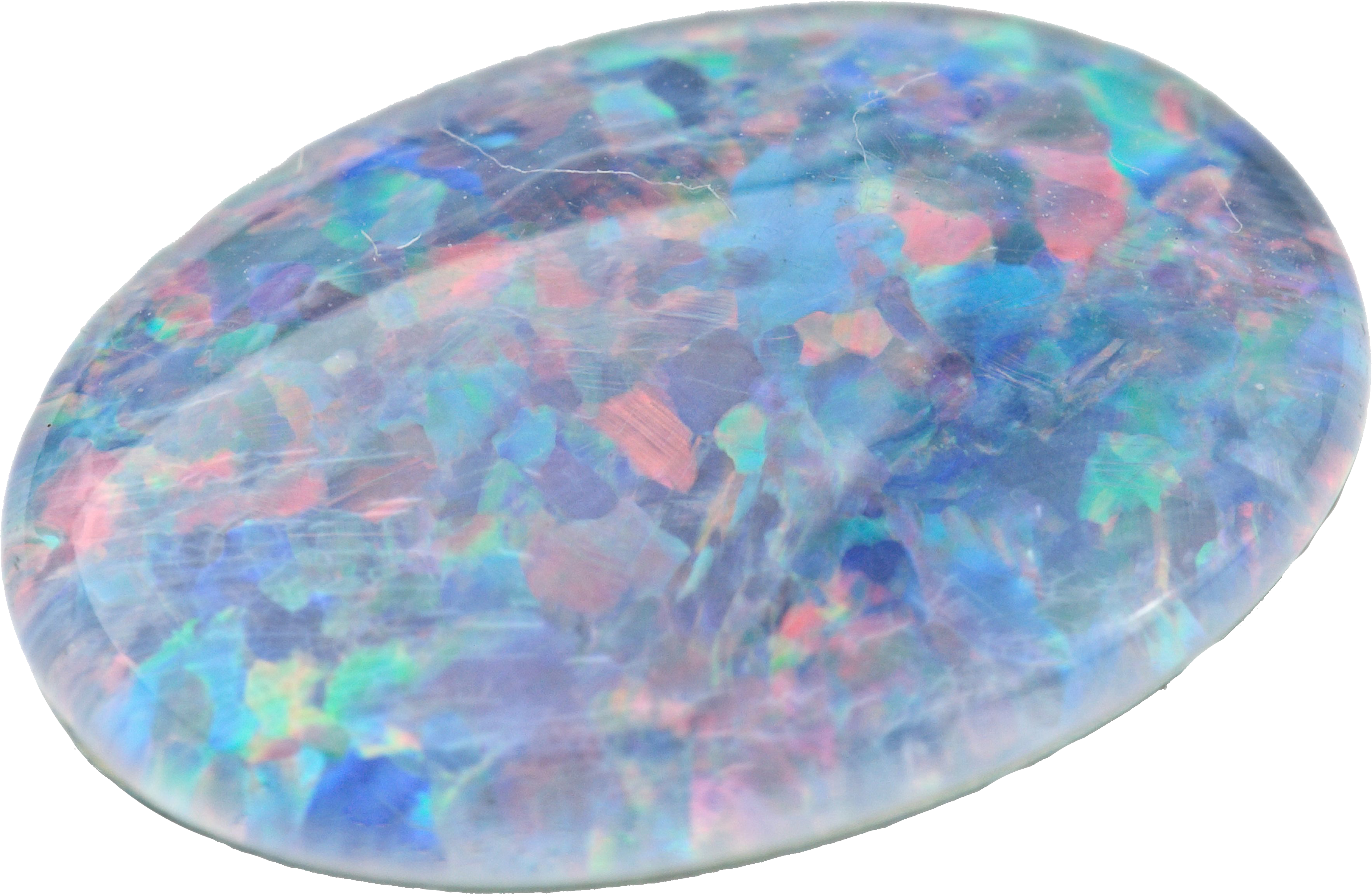

Just like any other gemstone, opal should be stored separately to your other stones and should be taken off when gardening, washing upm etc. to avoid any minor scratching that could occur. They can be polished with a soft toothbrush or a cloth to maintain their finish and even a little toothpaste with water can restore the opal to its original brilliance. (Toothpaste contains talc which is a light abrasive.)

Solid opals are made up from between 6 – 10 % water so placing your opal in a glass of luke warm water for 15 minutes every 12 months or so will help your opal and prevent it from drying out especially if the opal has been exposed to very dry conditions.

Equal to Jade on Moh’s hardness scale, opal is around 6.5. Not as tough as diamond but certainly easy enough to take care of. Common sense and knowledge about your opal is all you need in order to know how to take care of your opal.

Doublets and triplets have multiple layers and are best not to be in wet conditions for a prolonged period of time as this may cause a cloudy effect in the opal or cause it to delaminate from its layers. However well-made opal doublets and triplets will resist delamination and Australian Opal Cutters sell them with a lifetime guarantee against delamination.

Boulder opals are extremely fragile and delicate gemstones. If boulder opal jewelry is not properly taken care of, the layer of precious opal can crack and fade, which is known as ‘crazing’. Opals are fairly soft compared to other gemstones, making them extremely vulnerable to scratches and loss of polish. Although boulder opals are slightly more durable, they do still require a high level of care. It possible, store your boulder opal gems and jewelry in a dehumidified room, especially if you live in a dry climate. When storing opal gemstones for extended periods of time, place them inside a tight plastic bag with some type of moisture source, such as a damp tissue or cloth. This will prevent your precious opal from dehydration. Boulder opal is very sensitive to sudden temperature fluctuation, so try to keep boulder opal gemstones in a stable environment.